Problem Statement

In the heart of the data center universe, India’s one of the biggest Data centers, found itself facing a labyrinth of challenges that threatened its operational prowess. With the absence of a cohesive system for asset mapping, complaint resolution, and preventive maintenance, the giant from the data center industry needed to be grappling with inefficiencies, prolonged downtimes, and a foggy view of its maintenance landscape. Moreover, the lack of accurate, real-time information limited their ability to implement condition-based monitoring and predictive maintenance, leaving them dependent on reactive fixes instead of proactive asset care. As the pressures of mission-critical operations intensified, they sought a beacon of hope to revolutionize its maintenance processes and elevate asset management and other operational efficiencies to new heights of excellence.

As the problem statement above explains itself, this case study story will take you through all the major roadblocks in the seamless journey of a well-reputed data center and as a part of the solution how TeroTAM’s CMMS solution, helped them to get rid of it and witnessed the streamlined efficiency.

Major challenges faced by well-known data center in India

- Incomplete Asset Auditing and Location Condition Assessment

- Lack of Automated Work Order Creation and Technician Alerts

- Delayed Approval Management

- Complex Escalation Process for Breakdown and Red Flag Calls

- Limited Visibility into Historical Maintenance Data

- Difficulty in Monitoring Asset Condition Routinely

- Insufficient data for condition-based monitoring and predictive maintenance

- Manual Ticket Logging and Follow-up Process

- Inadequate Tracking of Warranty, AMC, and EOL Status

- Inappropriate Service Specification Configuration for Resource Allocation

- Absence of Decision-Support through Real-time Dashboards

- Challenges in Visualizing Historical Data for Performance Monitoring and Compliance Demonstration

How TeroTAM CMMS Helped a Data Center Giant Revive Operational Excellence

Infrastructural Asset Mapping:

Our CMMS software facilitated a seamless one-time entry of well-reputed data center’s infrastructure assets into the database. Through comprehensive infra-asset mapping, they have established a centralized repository, laying the foundation for efficient maintenance management.

QR Code-based Scanning and Complaint Management:

Our solution comprises a cutting-edge QR code-based scanning mechanism through the mobile app. This enabled on-site personnel to scan assets, triggering the app to raise complaints, preventive maintenance (PM), or general maintenance tasks using pre-defined checklists. Geo-tagging enhanced data accuracy and ensured physical verification.

Status Monitoring and Assignment:

With our system, the Data center gained real-time visibility into request status and streamlined assignments to their teams, departments, or vendors. This fostered collaborative and efficient maintenance workflows.

Sensor-based technology for predictive maintenance:

With our advanced sensor-based technology, the data center started receiving accurate real-time data on asset conditions. This enabled condition-based monitoring and predictive maintenance, shifting their operations from reactive to proactive. Based on sensor insights, automatic maintenance tickets were generated, ensuring timely intervention and reducing the chances of sudden breakdowns. This not only improved operational progress but also optimized resource usage and extended asset life cycles.

Six Options for QR Code Scanning:

Upon scanning the QR code, the app presented six options to choose from, empowering users to select: Breakdown Maintenance/Complaint Management, Preventive Maintenance, General Maintenance, Asset Details, Asset Auditing / Location Condition Assessment, and Bulk Maintenance.

Unique Pre-defined Checklists:

For each of the six options, our software required users to populate unique pre-defined checklists, ensuring standardized data entry for precise maintenance records.

Digital Recording of Preventive and Corrective Maintenance:

With our system, we helped them with digitized preventive and corrective maintenance records, offering a user-friendly drop-and-drag menu to select utilities, and streamlining data entry.

Three-tiered Maintenance Activities Management:

Our software solution efficiently manages maintenance activities across three levels: initial users conducting maintenance, supervisors overseeing site engineers, and DC managers overseeing the broader operations.

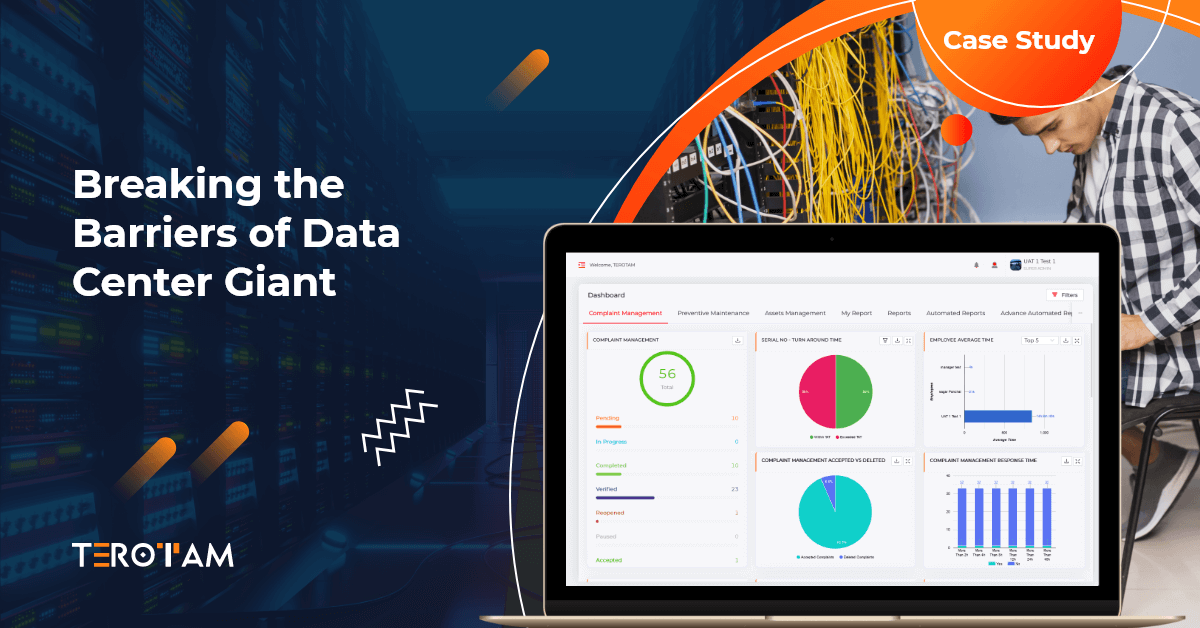

Customized Widgets and Dashboard:

We understand the importance of customization and hence offered customized widgets and a dashboard tailored to each user level. This personalized approach showcased relevant data, empowering users with real-time insights for smarter decision-making.

Alerts for Scheduled Maintenance and Inspections:

We have shaped our solution for them in a way that makes it capable of triggering alerts based on time or meter readings for scheduled maintenance and inspections. The dashboard displayed all sites, including flags and alerts, ensuring proactive maintenance.

Automated Work Orders:

The CMMS software automated the creation of work orders generated from helpdesk tickets and preventive maintenance plans. Technicians received alerts for upcoming work orders, equipped with unique instruction sets for each asset, optimizing performance.

AMC Notification and Escalation Management:

With our customized solution, Data center’s site managers received timely notifications on upcoming Annual Maintenance Contracts (AMC) by OEMs and vendors. In case of delays, the software handled escalations, ensuring AMC compliance.

Escalation of Breakdown and Red Flag Calls:

With this solution, they have strengthened and streamlined the escalation process for breakdown and red flag calls, ensuring timely attention and swift resolution.

Reports with Highlighted Warranty/AMC/EOL Status:

Each report generated by TeroTAM’s CMMS software highlighted the warranty, AMC, or End-of-Life (EOL) status, simplifying decision-making and planning for assets.

Configurable Service Specifications:

The software allowed them to configure service specifications, allocate resources based on skills and adhere to standardized work practices.

Pre-defined Templates for Utilities:

Our pre-defined templates benefit Data for various utilities, promoting consistent and efficient maintenance practices.

KPI/SLA Reporting and Real-time Dashboards:

Our customized CMMS software solution for Data center, provided ready-to-use KPI/SLA reporting and real-time dashboards, empowering Data center with data-driven insights for enhanced performance management.

To sum it up quickly, let’s trim the tale and unveil the heart of the matter

The data center giant partnered with TeroTAM to overcome inefficiencies in asset mapping, complaint resolution, and preventive maintenance. With QR code-based scanning, digital checklists, and real-time dashboards, they built a strong foundation for streamlined maintenance management.

The real breakthrough came with sensor-based technology, which provided accurate data for condition-based monitoring and predictive maintenance. Automatic ticket generation from sensor insights reduced sudden breakdowns, shifted operations to a proactive mode, and improved overall progress.

With analytics, escalation management, AMC tracking, and customizable dashboards, the data center gained full visibility and control over its assets. Together with TeroTAM, they transformed their maintenance process into a smarter, faster, and more reliable system that drives operational excellence.