Why You Need Manufacturing Maintenance Management Software?

The maintenance department and the manufacturing team are inextricably linked. Assets will break down and create bottlenecks if the production team ignores essential maintenance. On the other hand, if maintenance does not account for the production schedule, assets will become unavailable at inconvenient periods, causing disruptions. While production grows more automated and runs continuously, maintenance teams are challenged with finding time to do maintenance on profit-generating assets without slowing down the manufacturing process.

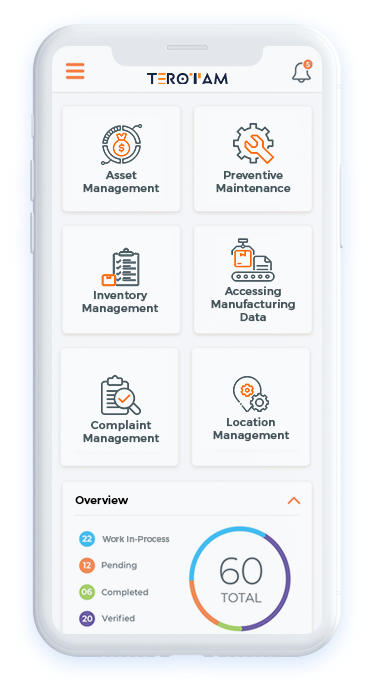

Manufacturing companies can use TeroTAM’s CMMS software to increase asset availability and dependability by scheduling maintenance intelligently. Make detailed preventative maintenance programs for your production assets. Examine the history of equipment repairs to spot recurring problems and make maintenance improvements. Other departments should be informed of the maintenance schedule to ensure that the equipment is ready for use. Stock only the quantity required to meet the demand to save money on inventory.

Capture the Reliable and Relevant Data in Real-time

Data capturing is simple with TeroTAM CMMS for manufacturing. The mobile app allows technicians to enter data straight into the system in real-time. Once it’s in the system, everyone on the team will be able to view the changes. Everyone uses the same data, which improves transparency and accountability.

Our user-friendly platform will give you a complete 360-degree picture of your plant’s data updates on a daily basis. Organize your plants with precise information in one central location, send it on to the appropriate person, and keep track of the routing task’s progress. Keep track of important dates, components, contracts, forecasts, work orders, and paperwork.

Our software will let you collect data from your monitoring system and organize it. No longer do you have to wait for your monthly reports to make data-driven decisions. In real-time, track the performance of assets, equipment, and workers.

Preventive Maintenance and Equipment Tracking

Our CMMS software assists you in implementing Preventive Maintenance in your manufacturing plants to avoid unplanned downtime for your assets and equipment. Flawless Equipment Tracking keeps you up to date on the state of each piece of equipment you own. Our software can help you set up a maintenance management system that suits your manufacturing needs.

Our software helps you assist your team in enhancing preventive maintenance, streamlining the work order workflow, and increasing the value of your assets. With improved maintenance practice, enjoy almost zero downtime to boost your productivity with streamlined workflow management.

You will be able to keep track of every movement of your equipment using a contemporary equipment tracking strategy with barcodes. Barcode lets you monitor and record each and every in and out of your equipment with complete details to use the information for better equipment control.

Standardized Inventory Management Process

The Manufacturing and Maintenance department can preserve exact data on inventories and spare parts with our CMMS software. This is especially important when dealing with expensive and hard-to-find inventory materials and parts, as well as the need to keep parts stocked at all of a company’s locations. Controlling inventory and spare parts can help you save a lot of money. They may quickly and simply search inventory for the items they need using TeroTAM’s CMMS software and have rapid access to them.

You can reduce downtime by ensuring your team has the parts and materials they need when they need them with inventory control. Set your par levels and have the software notify you when you’re running low.

By connecting components and materials with PMs and work orders, you can keep track of inventories automatically. Most importantly, prevent the stress of having operators stand motionless while technicians look for crucial parts.

Sky-Rocket your Manufacturing Efficiency with Cloud-based CMMS Software

TeroTAM’s CMMS Software Simplifies the Asset Management and Asset Tracking with a Centralized Dashboard

Manage your Manufacturing Business in a Palm-Easy Way with Smartphone

Create your own work request forms and allow guests to submit, Search, Sort, and Monitor requests using their mobile devices.

To avoid workers falling through the gaps, receive a notification when a task is assigned to you.

Keep track of how many parts you’ve used or how much labor you’ve done with your phone or tablet.

To lengthen the average lifespan of your assets, manage preventative maintenance of all your assets and equipment from your mobile device.

By scanning the QR code with your mobile device, you can keep track of your assets and see all of the updates on the go, at any time, and from anywhere.

Add photos to work orders and asset records from your camera or image gallery. You can identify issues, prepare for audits, and make clearer notes without breaking a sweat.

Advanced Features of Manufacturing and Maintenance Management Software

Industries We Serve

Maintenance

Education

Oil & Gas

Real Estate

Banking

Equipment

Healthcare

Non-Profit

Government

Fire Department/EMS

Hotels

Food & Beverage

Do you have questions?

Be a master in your domain with our CMMS tech solutions and smart ideas

What is the cost of Manufacturing Maintenance Management Software?

Each vendor has its own philosophy when it comes to software pricing, but industry experts say there are two sorts of pricing: monthly subscriptions and pay-as-you-go pricing. Contact us at contact@terotam.com to learn more about TeroTAM’s Manufacturing Maintenance Management software pricing.

Is it possible to keep the Maintenance Database and Documentation in one location?

Obviously, in Manufacturing Maintenance Management Software, all databases and paperwork will be stored on a cloud-based system that can be accessed from anywhere at any time.

Why is the Manufacturing Industry in Need of CMMS Software?

To run a successful manufacturing operation, it is necessary to manage a large amount of inventory, vendors, equipment, and assets. They also can’t afford any unscheduled downtime because they must fulfill manufacturing schedules and market demand. As a result, CMMS software must manage all assets, inventories, and vendors from a single system and use Preventive Maintenance to avoid unplanned downtime.

What Role does CMMS Software Play in Maintaining Compliance?

CMMS software provides you with the tools you need to keep your equipment and workplace safe, dependable, and compliant. KPIs and data that show compliance are available right away and are simple to report on.

What are the Benefits of using a CMMS in the Manufacturing Industry?

A Computerized Maintenance Management System (CMMS) helps manufacturers plan their operations, eliminates the great majority of unscheduled equipment maintenance, increases output, meets safety and regulatory standards, reduces costs, and responds promptly and comprehensively to emergencies.