Why Does the Mining Industry Need CMMS Software?

The mining industry operates in a highly demanding and hazardous environment where equipment reliability and operational efficiency are critical. CMMS software is essential for ensuring that mining equipment is maintained effectively, reducing the risk of unexpected breakdowns and costly downtime. With automating maintenance schedules, tracking asset performance, and managing work orders, CMMS software helps mining companies with mining equipment maintenance and maximize their uptime, extend the lifespan of their assets, and ensure safe working conditions. This level of organization and foresight is vital for minimizing operational disruptions and maintaining a steady production flow.

CMMS software provides mining companies with comprehensive data insights and analytics, enabling informed decision-making and strategic planning. With real-time monitoring and condition-based alerts, maintenance teams can proactively address potential issues before they escalate, enhancing overall equipment reliability. Detailed records of mining machinery maintenance activities, asset histories, and inventory levels facilitate efficient resource management and cost control. CMMS software empowers the mining industry to optimize its maintenance processes, improve operational efficiency, and achieve significant cost savings in the long run through effortless integration with these advanced features.

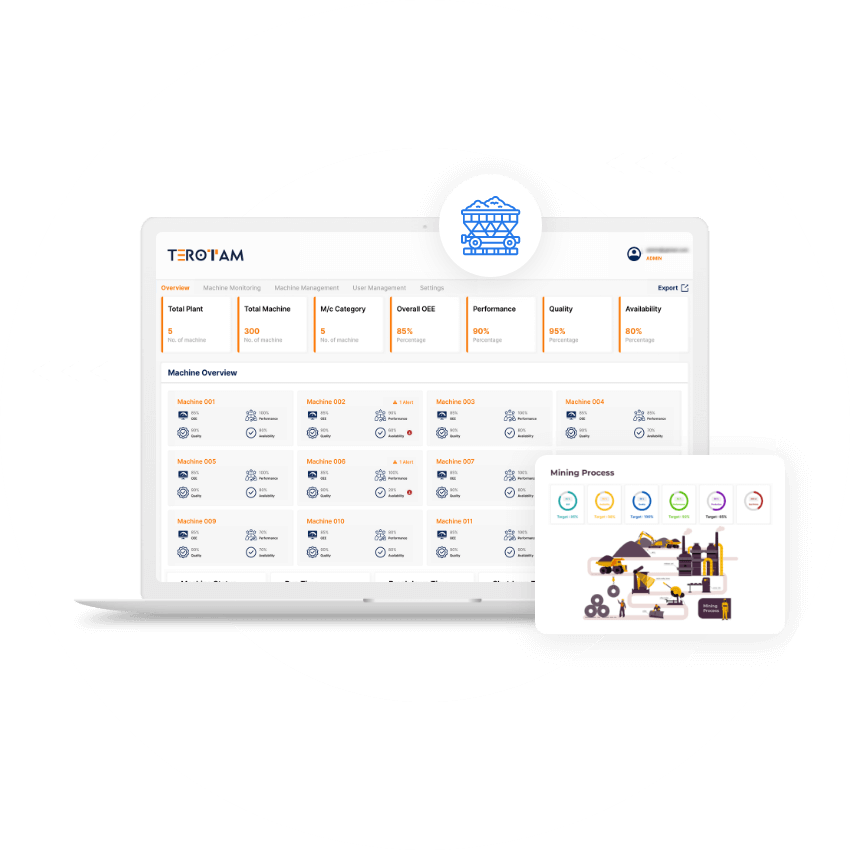

Comprehensive Mining Asset Management

Effective mining asset management is vital for maintaining operational efficiency and minimizing costs in the mining industry. Our CMMS can be your quick mining asset management software that helps you track, monitor, and optimize the performance and life cycle of mining equipment.

Regularly conduct physical verification of assets to ensure their existence and condition, preventing discrepancies between recorded and actual assets.

Utilize advanced tracking capabilities to maintain detailed records of all mining equipment and ensure an accurate overview of your assets enhancing overall asset management for mining companies.

With TeroTAM you got covered for every requirement of inventory management in mining companies that ensures the availability of necessary spare parts, reducing the risk of operational downtime.

Improve Equipment Reliability and Performance

The mining industry relies heavily on the optimal performance of its equipment and machinery. Downtime and equipment failures can lead to significant production losses and increased operational costs. CMMS software is crucial for mining maintenance ensuring equipment reliability and performance, helping you maximize productivity and minimize disruptions.

CMMS software ensures that all mining equipment is maintained at peak performance, reducing the likelihood of unexpected breakdowns and extending the lifespan of your assets.

With real-time performance data, CMMS software allows you to monitor equipment conditions continuously, identifying potential issues before they escalate into costly problems.

Keep a detailed record of all maintenance activities, repairs, and inspections, allowing you to make informed decisions based on historical data and trends.

Implement Condition-Based Monitoring

Condition-based monitoring is essential in the mining industry, where harsh environments can accelerate wear and tear on machinery. CMMS software enables condition-based monitoring to optimize maintenance schedules and improve equipment reliability.

CMMS software collects real-time data from sensors and other monitoring devices, providing a comprehensive overview of equipment health and performance.

Set up customizable alerts to notify maintenance teams of any deviations from normal operating conditions, allowing for timely interventions and preventing equipment failures.

Utilize diagnostic tools within the CMMS to analyze equipment performance data, identify potential issues early, and take corrective actions to prevent major breakdowns.

Avoid Unwanted Breakdowns with Proactive Maintenance

Proactive maintenance, including preventive and predictive maintenance strategies, is vital for the mining industry to avoid unwanted breakdowns and ensure continuous operations.

Automate preventive maintenance schedules to perform regular inspections and upkeep tasks, preventing equipment failures and maintaining optimal performance.

Utilize predictive maintenance techniques to anticipate potential issues based on equipment data and trends, scheduling maintenance activities before failures occur.

CMMS software aids in effective maintenance planning by providing detailed insights into equipment conditions, maintenance history, and future maintenance needs.

Revolutionize Your Mining Maintenance with CMMS

Discover the Benefits of a Modern Maintenance Management System for the Mining Industry

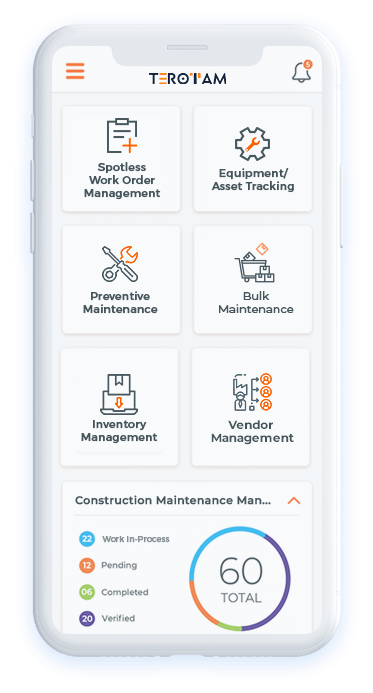

Manage Your Mining Operations with Ease

Manage maintenance tasks from anywhere with mobile-friendly access.

Automate routine tasks and workflows to maintain consistent standards.

Receive instant notifications about critical issues for immediate action.

Access schedules, work orders, and asset info on your mobile device.

Use integrated tools for team communication and task tracking.

Optimize inventory and workforce allocation for efficient maintenance activities.

Features of Mining Maintenance Software

Industries We Serve

Maintenance

Education

Oil & Gas

Real Estate

Banking

Equipment

Healthcare

Non-Profit

Government

Fire Department/EMS

Hotels

Food & Beverage

Do you have questions?

We know the most obvious doubts one has in mind while thinking of Asset Management Solution. Check out FAQs and unravel your doubts.

What role does CMMS software play in preventive maintenance for mining equipment?

CMMS software helps plan and schedule regular preventive maintenance tasks, ensuring that all equipment receives timely inspections and servicing. This proactive approach minimizes the risk of unexpected breakdowns and extends the lifespan of mining assets.

Can CMMS software help in tracking the maintenance history of mining equipment?

Yes, CMMS software maintains detailed records of all maintenance activities, including repairs, inspections, and parts replacements. This comprehensive maintenance history helps identify recurring issues and optimize maintenance strategies.

What are the benefits of integrating CMMS software with IoT devices?

Integrating CMMS software with IoT devices allows for real-time data collection and monitoring of equipment conditions. This enables predictive maintenance, immediate issue detection, and efficient resource management, enhancing overall operational efficiency.

Can CMMS software integrate with other systems used in mining operations?

Yes, CMMS software can integrate with various systems such as ERP (Enterprise Resource Planning), SCADA (Supervisory Control and Data Acquisition), and IoT (Internet of Things) devices. This seamless integration enhances data visibility and operational efficiency.