Why You need CMMS for Maritime Industry?

The tracking of assets, assemblies, and parts related with the vessel installation is provided by TeroTAM’s Ship Maintenance System. The DNV GL type certified product can be customised to meet the needs of the manufacturer/class. The module includes capabilities such as task pre-planning and scheduling, as well as cost and time forecasts. Pre-planning capability allows for resource, time, and spares planning, all of which are important in inventory management based on predictive and preventative maintenance routines.

Our System seeks to maintain safe and dependable vessel operations by allowing ship owners and management to plan, perform, and document vessel maintenance while remaining compliant with Class and manufacturer regulations. To efficiently meet safety and environmental regulations, our System is tailored to the vessel type, class, and any additional criteria and measures.

Centralised Ship Maintenance

Centralised Ship Maintenance system allows you with an eagle-eye view of each and every activities and assets being used in those activities. It helps you Plan your Regular and Daily activities, schedule the work plans and assign them to respective crew members with relevant performance tracking to take relevant corrective actions.

Our Centralised Dashboard – A one-of-a-kind offshore planned maintenance dashboard that provides details of completed and scheduled planned maintenance, and maintenance total man-hours (estimated / real) for the current year in a tabular and graphical format (monthly and quarterly).

Report completed work, take measurements, divide and distribute jobs to different resources, track completion progress, and keep track of expenditures based on reported hours.

Highly Scalable Maintenance System

Our Ship Maintenance System is built in such a way that you can store and access all the necessary information as and when you actually need it. You can build an enigmatic Database system that helps you fetch all the necessary inputs to make the right decision and plan and schedule crew members jobs and maintenance activities.

With Our software Data can be Built to ensure equal application across the fleet, allowing for simple commissioning, data administration, and reporting. Data can also be sorted and listed to display individual assets and operational status.

Work history, scheduled jobs, spare parts, calibrations, specs, reports, and documents can all be stored and transferred using our Ship Maintenance System. It is possible to optimise maintenance and save downtime by exchanging these facts.

Up-to-date Work Ordering System

The Most important factor in any maintenance system is an accurate work ordering system that helps the management and the crew members to get alerts and notification about when and what kind of activities they need to perform and also help them to analyse the route cause for the down-time to take progressive actions.

Work Order reporting allows for reporting of details such as downtime hours, time returned to operation, time of receipt of notification of problems, time of diagnosis of problems, time problems are fixed, and associated costs – if any – that are required for future analysis of overall equipment efficiency.

Work Order reporting enables the reporting of failure causes and modes, assisting in the early discovery and elimination of probable product/process failure modes, as well as possible predictive maintenance.

Optimise your Work Order Process with Marine Maintenance Software

Streamline your Work Orders and Schedule Maintenances with a System that built to Perform

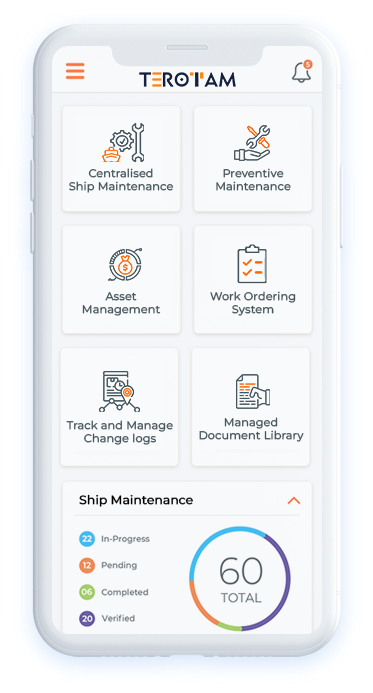

Manage your Marine Business in a Palm-Easy Way with Smartphone

Get a complete overview of the Ship Maintenance on Centralised Dashboard through your Smartphone anytime anywhere you need.

Create and Assign Work Schedules for Maintenance team through your Smartphone in case of urgency to avoid downtime

Generate Job orders and assign a team to give them notification on their smartphones to reduce the chances of missing out.

Generate and Scan the QR codes for the assets and scan them through you Smartphones to get all maintenance history and future schedule

Upload and Update Documents through your Smartphone to keep the ship document management system up-to-date with copies of manuals and other documents.

Access Detailed Work Hour Logs on your Smartphone to track the performance on the go.

Advanced Features of Ship Maintenance System

Industries We Serve

Maintenance

Education

Oil & Gas

Real Estate

Banking

Equipment

Healthcare

Non-Profit

Government

Fire Department/EMS

Hotels

Food & Beverage

Do you have questions?

Let’s make it clear with your queries, and be tech-savvy in your business

What is a Ship Maintenance System?

According to the International Safety Management Code, ships must have a ship maintenance system (ISM). It requests that the corporation implement procedures to guarantee that the vessel is kept in compliance with all rules and regulations.

What are Shipping Documents?

Shipping documents are the forms, records, or certificates required for a shipment’s delivery or clearance through customs.

Why to Invest in a Ship Maintenance System?

The ship PMS software gives management a bird’s eye view of all data related to the fleet and its performance.

Why is the Ship Management System Beneficial for Marine Industry?

The Marine Companies benefit from TeroTAM’s Ship Maintenance System by having smoother workflows, better user management, appropriate data access for users, and secure and strong data transfer between the ship and onshore superintendents.

What role does the Ship Maintenance System play in Marine Business?

The Ship Maintenance System that is also known as Marine Maintenance Software, eliminates the drudgery of ship management on a daily basis. The platform serves as a single repository for all data related to your fleet, eliminating the confusion generated by data scattered over numerous disconnected platforms, resulting in data silos.