Why Do You Need CMMS Software for Chemical Industry?

Nearly every element of our lives—including the food we consume, the clothes we wear, our health and hygiene, and our environment—is impacted by the chemical industry. A highly reliable set of tools functioning in a well-regulated and monitored environment are necessary for safe chemical manufacture. Even little changes in temperature, moisture content, pH, and other factors can lead to the production of new compounds with unique properties, some of which may be seriously dangerous. Stable production, as well as the health and safety of individuals working in the chemical manufacturing industry, depend on effective maintenance.

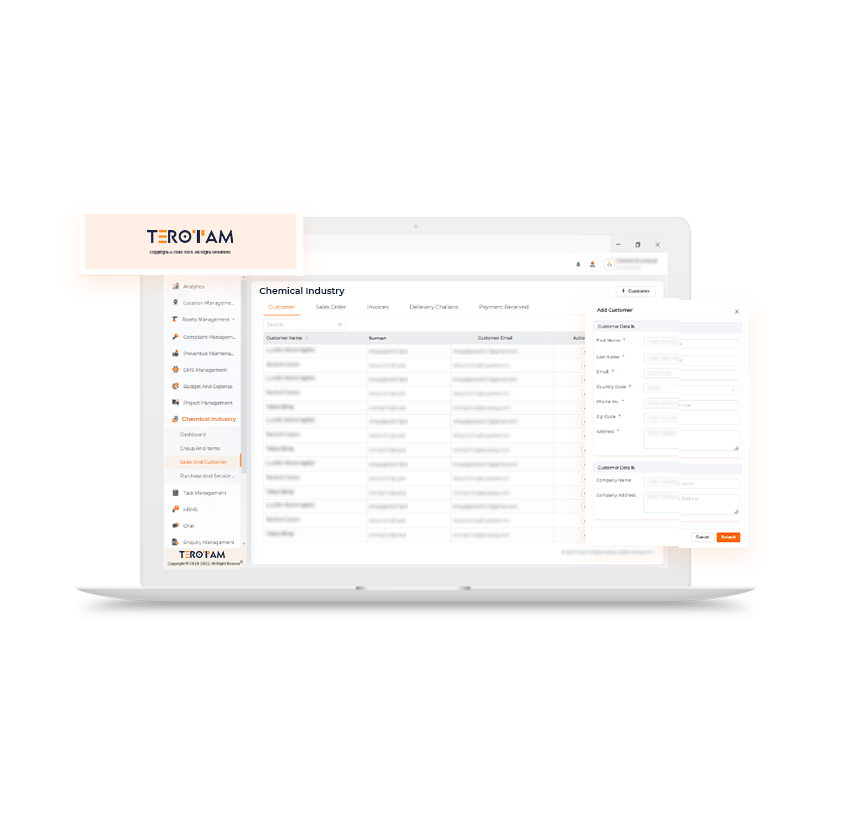

Chemical firms now have a consolidated platform for recording asset data and maintenance tasks to cut down on downtime thanks to TeroTAM CMMS software. In order to establish maintenance methods to stop further failure, asset tracking features can help you understand why equipment malfunctions. You may make unique maintenance plans for every asset in your organization using comprehensive preventive maintenance scheduling tools. By monitoring asset management key performance indicators (KPIs) and other metrics, maintenance reports assist you in making knowledgeable maintenance management decisions.

Accurate Asset Data Management and Monitoring

Utilizing TeroTAM CMMS for Chemical Industry makes data collection straightforward. Technicians can enter data directly into the system in real-time thanks to the CMMS software’s mobile friendliness. Everyone on the team will be able to see the modifications after it is entered into the system. Since everyone utilizes the same information, accountability and openness are improved.

Our easy-to-use software will provide you with a complete 360-degree view of your chemical plant’s data updates daily. Put all of your plants’ precise information in one place, transmit it to the right person, and monitor the routing task’s development.

You may manage and collect data from your monitoring system using our software. Making data-driven judgments doesn’t require you to wait for your monthly reports any longer. Monitor the efficiency of your people, equipment, and resources in real-time.

Standardized Work Order Management

Administrators in chemical plants can assign the right people to the right jobs using our CMMS software. This consists of manual or automated work orders for technicians performing plant maintenance. The technicians can then be notified automatically of any new work orders. They can change a job’s status, add comments, and mark tasks as finished using the CMMS.

Efficiency in Chemical plants is directly attached to Work Order Management. In-house operational efficiency is ensured by effective work order administration, which maintains all the work immaculately arranged. It keeps the workflow smooth and streamlined and ensured ongoing operations.

With no latency, unexpected stoppages, or unforeseen priority, a well-managed work order maintains productivity and staff morale at a high level. Employees know what they are supposed to do and how to do it. There is no scope for confusion and work dilemmas that stops them to perform.

Methodical Preventive Maintenance Approach

To prevent unplanned downtime for your assets and equipment, our CMMS software helps you execute preventive maintenance in your chemical plants. Your knowledge of the condition of each piece of equipment you own is kept current by Flawless Equipment Tracking. Our software can assist you in establishing a maintenance management system that meets the demands of your chemical industry organization.

With the aid of our software, you can support your team in improving preventative maintenance, optimizing the workflow for work orders, and raising the asset value. Enjoy nearly zero downtime thanks to updated maintenance procedures, which will increase your productivity through better workflow administration.

A modern equipment tracking method using QR codes will allow you to monitor every movement of your equipment. The ability to track and record every piece of equipment entering and leaving your possession with full details using a barcode enables you to improve equipment control.

Clocklike Inventory Management and Control

With the help of our CMMS software, chemical plant asset managers can maintain accurate data on inventory and replacement parts. This is crucial when working with costly and difficult-to-find inventory materials and parts, as well as when maintaining the stock of parts throughout all of a company’s locations. Using the CMMS software from TeroTAM, they can easily and rapidly search the inventory for the things they require and have instant access to them.

By using inventory control, you can minimize downtime by making sure your team has the components and supplies they require when they need them. You may program the CMMS software to alert you when you run low on your par levels and automate the orders on Preset Re-order Points.

Reduce the cost of your inventory to the ideal level by limiting unauthorized orders and excess quantities of spare parts and commodities. Manage the Economic Order Quantity that suits your company’s needs and budgets by tracking the Inventory issuance and usage trend.

Redefine Your Operational Excellence with Advanced CMMS System

Take Your Plant Asset Management to the Next Level with State-of-the-art Technology

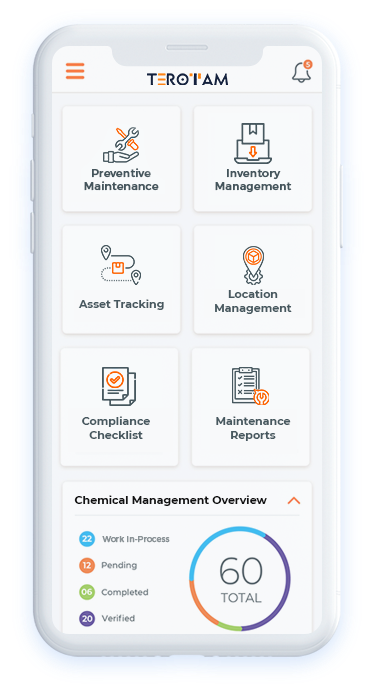

Manage your Chemical Plants in a Palm-Easy way with Smartphone

Utilize your smartphone, which is the most convenient gadget, to keep track of all the assets and inventories wherever you go.

Bring your smartphone into action to manage the preventative maintenance of all of your assets and machinery to increase the average asset lifespan.

Create tasks for your team, assign them, and send them alerts with personalized checklists to their mobile devices.

Scan a QR code to track your assets and get real-time updates wherever you are with your mobile device.

Advanced Features of CMMS for the Chemical Industry

Industries We Serve

Maintenance

Education

Oil & Gas

Real Estate

Banking

Equipment

Healthcare

Non-Profit

Government

Fire Department/EMS

Hotels

Food & Beverage

Frequently Asked Questions:

How a CMMS may help with Chemical Plant Asset Management?

As technology advances daily, new asset-tracking technologies can be employed for better experiences. As more information is provided, more customers will feel satisfied.

How Does Downtime Impact Chemical Plants' Productivity?

When an asset ceases functioning, it sets off a series of events that cause the process to slow and stop, which accelerates loss. It consequently causes confusion and delays in operations at your chemical factories.

What are the Benefits of using a CMMS in the Chemical industry?

A Computerized Maintenance Management System (CMMS) assists managers of chemical plants in planning their operations, eliminate the vast majority of unscheduled equipment maintenance, boosts output, complies with safety and regulatory requirements, lowers costs, and provides prompt and thorough emergency response.

What is the Cost of CMMS for the Chemical Industry?

Every CMMS provider has a different attitude when determining the price of their software, but according to companies in the market, there are two different pricing models: fixed monthly cost and pay-per-use pricing. Contact us at contact@terotam.com to learn more about the pricing for TeroTAM’s Chemical Plant Asset Management solution.

How does TeroTAM’s CMMS Software for Chemical Industry Work?

Utilizing the well-thought-out capabilities of TeroTAM’s chemical plant management software, you can efficiently plan and carry out preventive maintenance, asset management, and tracking with a clear workflow structure. It helps you streamline your operations against all odds and ensures smooth workflows within the organization.