The manufacturer and dealer of the industrial packaging and filling line is a multinational firm that has been in the business for decades and provides innovative machine solutions to businesses. But, while they are growing in their business, they face multiple challenges while dealing with their plant, delivery and especially with customer service as it is the main concern to keep the business on track with the right brand image in the market.

Statement of the problem

The Manufacturer and Dealer of Packaging lines were under great pressure to keep their equipment running most of the time and ensure quick response to service calls while dealing with a complex network of service schedules and maintenance records.

According to them, this has led to fragmented communication channels and poor planning regarding maintenance activities, leading to prolonged downtimes, thus diminishing customer satisfaction, among other things.

Challenges

Inefficient tracking system for maintenance services:

Previously, this client used manual methods to track what needed to be done where, consequently resulting in frequent breakdowns and wasted resources.

Delayed response time:

Customer satisfaction was compromised when there were slow or uncoordinated responses to customers’ requests for assistance with services rendered.

Inventory control problems:

Poor management in terms of stock levels vis-a-vis demand patterns affected efficiency levels within various departments involved directly with the provision of these services across all branches globally.

Data Discrepancies:

The lack of a centralized data system led to inconsistencies in maintenance records and difficulty in tracking equipment lifecycle across different locations.

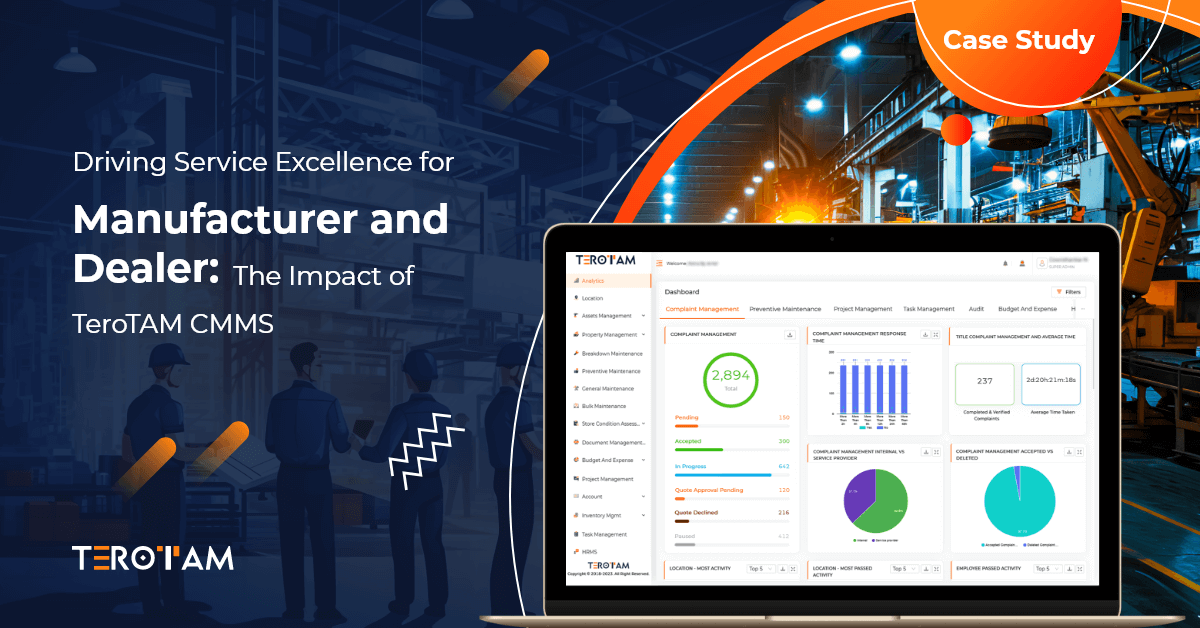

Solution with TeroTAM CMMS Implementation

While discussing the challenges, we gained some insights into what solutions we can offer the client to streamline and systematize everything. After our discussion, we started implementing the CMMS solution for the client with the solutions below and their impact.

Automated Maintenance Scheduling:

TeroTAM’s CMMS provides automated preventive maintenance scheduling based on real-time equipment data and usage patterns.

Impact

- Reduced equipment downtime by 40% which increased availability and operational readiness.

- Optimized workforce allocation that enhanced productivity by reducing redundant labor.

- Increased efficiency of preventive maintenance schedules that lowered maintenance costs.

- Timely intervention of routine maintenance which improved equipment lifespan.

- Supporting better asset utilization through enhanced overall equipment effectiveness (OEE) metrics.

Real-Time Service Request Tracking:

The system logs, assigns and tracks all service requests in a central platform in real time.

Impact

- Service lifecycle is significantly sped up by decreasing service request initiation time.

- Quicker diagnostics and resolution are facilitated through improved accuracy of reported issues.

- Immediate acknowledgement and tracking of requests improves customer experience greatly.

- Precise maintenance actions are ensured while reducing miscommunication errors.

- Higher first-time fix rates are achieved due to technician preparedness being boosted.

Workflow-Driven Escalation Management with TAT:

The CMMS has a workflow engine that escalates issues based on TAT (time-to-action) metrics and predetermined thresholds.

Impact

- Customer satisfaction is increased by ensuring adherence to SLAs through automated escalations.

- Urgent issues are automatically prioritized hence reducing resolution times.

- Even during peak loads services remain consistent because workflows are managed efficiently.

- Traceable, time-stamped actions in the system lead to increased accountability.

- Operational transparency is enhanced thus improving trust and relationships with clients.

Inventory Management Optimization:

TeroTAM CMMS comes with an advanced inventory management module that predicts inventory needs based on maintenance trends.

Impact

- Excess inventory costs are reduced and stockouts cases minimized.

- Directly during maintenance parts availability is improved leading to reduced equipment downtime .

- Optimizing warehouse space and resources because of just-in-time inventory practices enabled.

- Better forecasting leads to reduced financial losses from obsolete or excess inventory.

- Efficiency is improved as well as lead times in streamlined procurement processes.

Tracking of Equipment Delivery at Each Destination Point via QR Scanning:

Each equipment unit has a unique QR code which is scanned at various checkpoints during delivery.

Impact

- Logistics management is improved through real-time updates on equipment status and location.

- Accurate and timely arrival of equipment is ensured by reducing delivery discrepancies.

- Security throughout the delivery process is enhanced; this also makes every person accountable for what they do.

- Monitoring each scan point enables taking corrective actions immediately during transit.

- All stakeholders are kept informed hence facilitating smoother handovers and installations.

Data Centralization and Analytics:

The platform centralizes data from different sources for detailed analytics on equipment performance, technician productivity, and maintenance costs.

Impact

- Strategic decisions are enhanced by unifying disparate data sources that give a holistic view of operations.

- Continuous process improvement is achieved through operational bottlenecks identification as well as addressing them accordingly.

- Equipment usage analytics allows for predictive maintenance based on data trends.

- Real time actionable insights enable increased operational agility.

- Reporting capabilities are strengthened thus ensuring regulatory adherence

Conclusion:

The implementation of TeroTAM’s CMMS brought a significant transformation in both customer service and maintenance operations. Beyond streamlining internal workflows, it empowered the team to deliver faster responses, real-time data visibility, and improved communication—leading to a noticeable enhancement in service quality.

Post-implementation metrics showed impressive results: downtime reduced by 40%, response time improved by 25%, and maintenance costs dropped by 30%. For the client, maintaining high-performing, reliable equipment became a standard expectation—and TeroTAM’s CMMS proved to be a critical tool in consistently meeting that standard.