Maintenance management goes beyond fixing machines; it’s about ensuring the reliability and safety of assets while minimizing risks. Among the many tools available, Event Tree Analysis (ETA) stands out as a practical method for assessing the ripple effects of unexpected events. Whether it’s a minor equipment hiccup or a major system failure, ETA provides a clear picture of what might happen next—and how to prepare for it.

If you’ve ever wondered how maintenance teams stay a step ahead of potential disasters, Event Tree Analysis might just hold the answer.

Understanding Event Tree Analysis in Maintenance Management

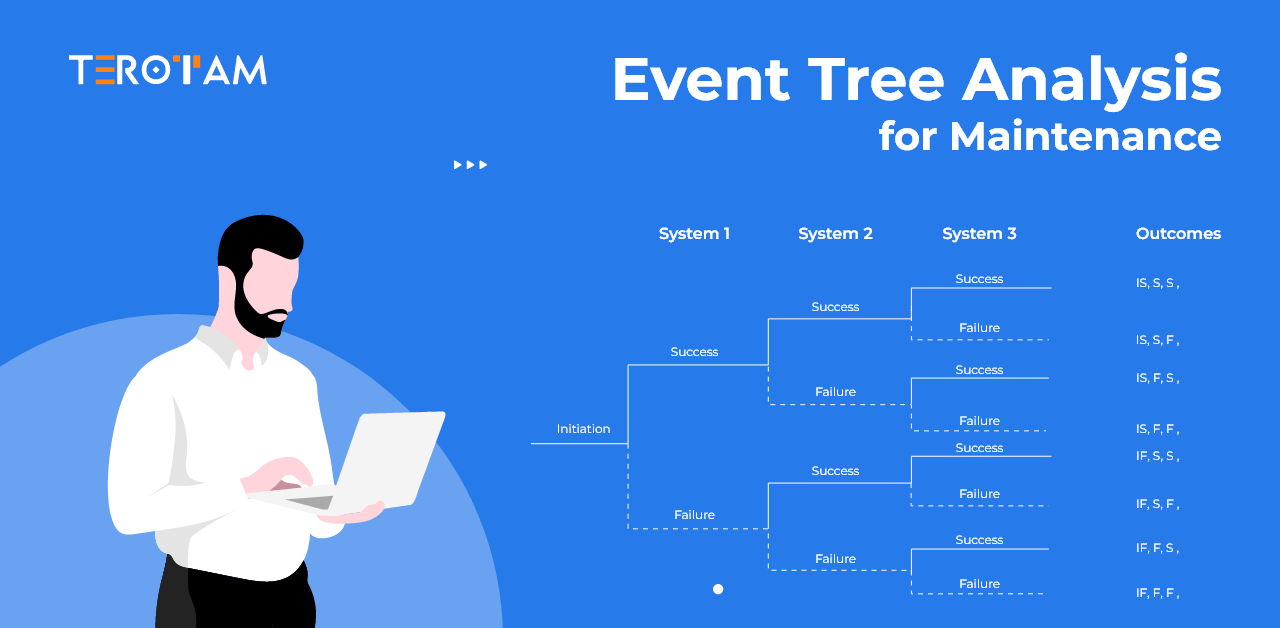

Event Tree Analysis is like mapping out a story—but with equipment, systems, and processes as the characters. It starts with a single event, such as a machine breakdown or a power surge, and branches out into all the possible outcomes. Each branch represents a decision point or reaction, helping you visualize what could go right, what might go wrong, and everything in between.

For maintenance teams, this approach is invaluable. It helps anticipate the domino effect of a failure and guides decisions to keep operations running smoothly.

Breaking Down the Basics of Event Tree Analysis

With its deep routed problem finding nature, Event Tree Analysis revolves around a few key elements:

- The Starting Point: This is the “what if” moment. It could be anything from a pump failure to a human error during routine maintenance.

- The Branches: These represent different responses or system behaviors triggered by the starting point, like an alarm activating or a safety valve failing.

- The Outcomes: These are the results of the chain of events, ranging from minor inconveniences to full-blown operational shutdowns.

- The Likelihoods: Each branch comes with a probability, showing how likely that specific outcome is. This part relies on data, expertise, or sometimes a mix of both.

How Does Event Tree Analysis Work in Maintenance?

Think of ETA as building a roadmap to explore all the possible paths an event could take. Here’s how it typically unfolds:

- Define the Problem: Start by identifying the initiating event you want to analyze—like a sudden compressor failure.

- Explore the Chain Reactions: Map out everything that could happen next. Will the backup system kick in? Will alarms alert the team in time?

- Sketch the Event Tree: Visually lay out each branch, starting from the initiating event and expanding into all the potential responses.

- Assess Probabilities: Use past data or expert input to assign probabilities to each branch. This step highlights which scenarios are most likely.

- Examine the Outcomes: Evaluate the impact of each potential outcome—downtime, repair costs, safety risks, or even regulatory penalties.

- Create an Action Plan: Based on your findings, decide how to reduce risks or improve systems to handle events more effectively.

Why Use Event Tree Analysis in Maintenance?

“what ifs” is a game-changer. ETA offers insights that help teams avoid costly downtime, prioritize safety, and optimize maintenance schedules. Now, just think once, knowing not just that a failure could happen but also how it might unfold—and having a plan ready to respond.

Here are some of the benefits ETA brings to the table:

- Informed Decisions: With a clear picture of potential risks, teams can allocate resources more effectively.

- Cost Control: Spotting issues before they escalate saves money on repairs and prevents production losses.

- Safety First: Visualizing outcomes ensures that safety measures are robust and compliant with regulations.

- Better Planning: Knowing what’s likely to happen helps streamline maintenance schedules and reduce unexpected surprises.

Where Does Event Tree Analysis Apply in Maintenance Management?

Event Tree Analysis shines in various maintenance scenarios:

- Preventive Maintenance: Determine when and where failures might occur to plan timely maintenance.

- Root Cause Analysis: Understand how past events could have been avoided by tweaking maintenance strategies.

- Emergency Response: Evaluate the reliability of safety systems like alarms or fire suppression.

- Maintenance Prioritization: Focus on high-risk areas to maximize efficiency and minimize risks.

Why It Matters?

Event Tree Analysis empowers maintenance teams to turn uncertainty into actionable insights. It’s about more than predicting problems; it’s about creating strategies to prevent them or mitigate their impact. This approach can make all the difference in industries where a single failure can ripple through an entire operation.

Understanding ETA could be your first step toward smarter maintenance and safer operations, whether you’re managing a small workshop or a large industrial facility. Want to know more? – Reach out to our maintenance experts at contact@terotam.com