Have you ever been in a situation where your phone suddenly stopped working, or your car broke down on a busy highway, leaving you stranded? In those frustrating moments, you might have wondered, “Could this breakdown have been predicted, and the hassle avoided?” Now correlate this same situation with your manufacturing business.

Your order delivery date is on arrival and your machine went on breakdown. Now your production and delivery will be delayed. Again you will be thinking whether you could avoid this unwanted downtime?

The answer lies in a fascinating metric known as Mean Time Between Failure. In this discussion today, we’ll embark on a journey to demystify MTBF, understanding what it is, why it matters, how to calculate it, and how this metric can be a game-changer in maintenance management.

What is the Mean Time Between Failure?

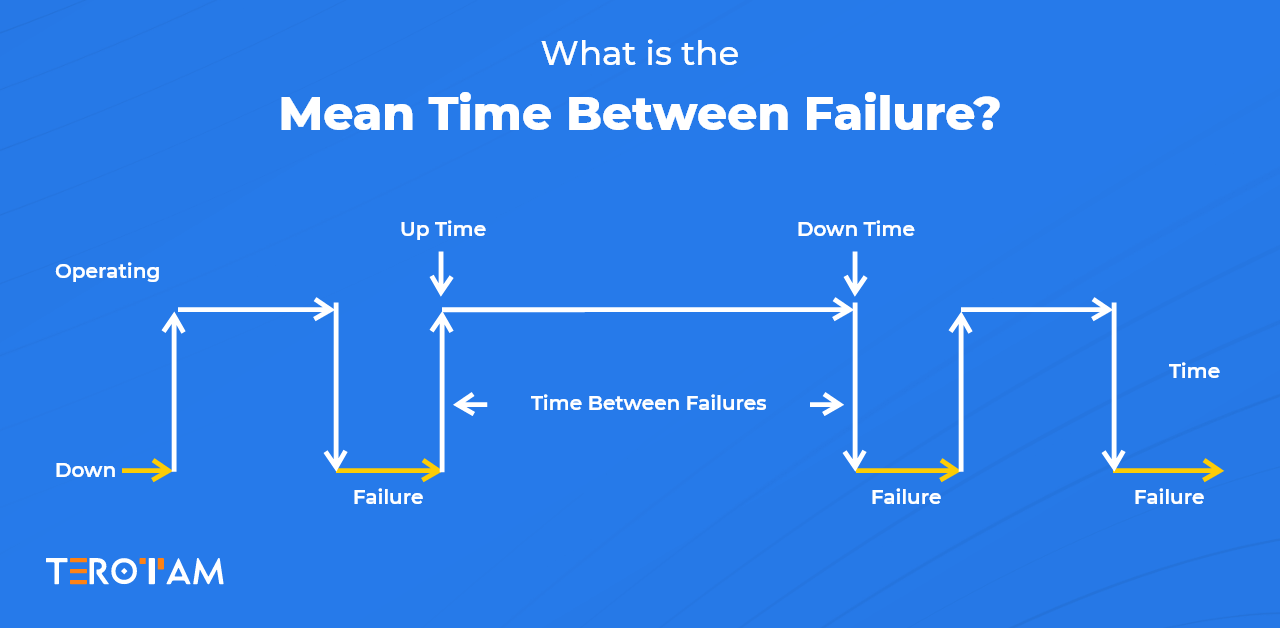

Mean Time Between Failure is a fundamental reliability metric used across various industries to assess the expected time interval between the failure of a component, device, or system.

In simple terms, it answers the question: “On average, how long can we expect a piece of equipment to operate without experiencing a failure?”

MTBF is expressed in the unit of time, typically hours or years, and represents the average time a system or component functions correctly before encountering a malfunction or breakdown. It is an invaluable parameter for businesses and organizations, as it allows them to plan maintenance activities, predict downtime, and ensure continuous operations.

How to Calculate Mean Time Between Failure?

Calculating MTBF involves straightforward mathematical procedures, but it’s important to consider the specifics of your equipment and data collection.

The basic mean time between failures formula is:

MTBF = Total Operating Time/Number of Failures

To ensure accurate results, follow these steps:

Determine Total Operating Time: This is the cumulative time the equipment operated without failures. Record this time in hours or another relevant unit.

Count Failures: Keep track of the number of failures that occurred during the observed period.

Plug into the Formula: Use the formula above to calculate MTBF by dividing the total operating time by the number of failures.

Unit Consistency: Ensure that the units of total operating time and MTBF are consistent, whether in hours, days, or years.

Advantages of Mean Time Between Failure

Reliability Assessment:

MTBF provides a quantitative measure of reliability, allowing organizations to evaluate the trustworthiness of their equipment and systems. A higher MTBF value indicates greater reliability.

Maintenance Planning:

Maintenance teams can plan their activities more effectively by knowing the expected time between failures. This leads to cost savings through optimized maintenance schedules and reduced downtime.

Warranty and Service Contracts:

Manufacturers often provide warranties based on the MTBF of their products. A higher MTBF can translate to longer warranty periods, saving money for both consumers and businesses.

Performance Benchmarking:

MTBF enables organizations to compare the reliability of different equipment or systems. It aids in making informed decisions about purchasing, upgrading, or replacing assets.

The Relationship Between MTBF and Preventive Maintenance (PM)

Preventive Maintenance (PM) and Mean Time Between Failure are intimately intertwined concepts that form the backbone of effective equipment and system maintenance strategies.

a. Predictive Maintenance Scheduling:

MTBF data plays a pivotal role in preventive maintenance scheduling. Organizations use the derived value as a key input to determine when preventive maintenance tasks should be performed. Specifically, when the MTBF of a system decreases or falls below a certain threshold, it signals that the equipment may become less reliable or prone to failure.

b. Frequency Adjustment:

As the Mean time decreases, organizations adjust the frequency of preventive maintenance tasks accordingly. PM activities can be less frequent when the Mean time is high, indicating a reliable system. Conversely, as the MTBF decreases, PM becomes more frequent to maintain the equipment’s reliability.

c. Cost-Efficiency:

The close relationship between MTBF and PM helps organizations strike a balance between maintenance costs and equipment reliability. When the mean time is high, less frequent PM, activities can lead to cost savings. Conversely, when Mean time decreases, investing more in preventive maintenance can be cost-effective compared to the expenses associated with unexpected breakdowns.

d. Risk Mitigation:

Organizations can effectively mitigate the risk of equipment failures by using such data to guide PM schedules. This proactive approach reduces the chances of costly disruptions in production, service delivery, or critical operations.

e. Data-Driven Decision Making:

MTBF provides organizations with concrete data for decision-making. When combined with historical maintenance records, it enables organizations to fine-tune their PM strategies, ensuring they align with the equipment’s actual performance.

Conclusion

In the world of maintenance management, Mean Time Between Failure stands as a beacon of reliability. It empowers organizations to assess, plan, and optimize their maintenance activities, leading to increased uptime, cost savings, and enhanced operational efficiency. By understanding the definition, advantages, calculation methods, and its role in maintenance management, businesses can harness the power of MTBF to keep their systems running smoothly and their bottom lines healthy.