Maintenance is a critical aspect of any industry that relies on machinery and equipment. Ensuring optimal performance, safety, and efficiency often requires different types of maintenance strategies. Among these, corrective maintenance plays a significant role.

But, what exactly is corrective maintenance?

This article delves into its meaning, workflow, examples, and how it differs from other maintenance types like preventive and predictive maintenance. Additionally, we’ll explore ways to minimize the need for corrective maintenance.

Understanding Corrective Maintenance

Corrective maintenance plays a critical role in asset and facility management. It involves identifying and fixing equipment or system issues after a failure occurs. This reactive maintenance strategy is essential for restoring operations quickly, minimizing downtime, and keeping workflows running smoothly.

Corrective Maintenance Definition

Corrective maintenance, sometimes referred to as reactive maintenance, involves identifying and rectifying faults in equipment or machinery after they occur. This type of maintenance is performed when a piece of equipment has failed or is operating below acceptable standards. The goal is to restore the equipment to its normal operating condition.

Corrective Maintenance Workflow: How Does It Work?

The workflow for corrective maintenance typically follows these steps:

- Detection: Identify a fault or failure in the equipment.

- Diagnosis: Analyze the problem to understand its cause and extent.

- Planning: Develop a plan to repair or replace the faulty components.

- Execution: Carry out the repair or replacement tasks.

- Testing: Ensure that the equipment is functioning correctly after the maintenance.

- Documentation: Record the issue, actions taken, and any observations for future reference.

This workflow ensures that all necessary steps are taken to address the issue effectively and efficiently.

Example of Corrective Maintenance

Consider a manufacturing plant where a conveyor belt suddenly stops working. The maintenance team first detects the issue, diagnoses it as a motor failure, plans the motor’s replacement, executes the replacement, tests the conveyor belt to ensure it’s working correctly, and documents the entire process. This is a typical example of corrective maintenance in action.

Advantages of Corrective Maintenance:

- Simplicity: Easier to implement as it doesn’t require regular monitoring or complex planning.

- Immediate Focus: Directly addresses and fixes the specific issues that have caused equipment failure.

- Cost-Effective Short-Term: Lower immediate costs compared to preventive maintenance, as it only incurs expenses when a problem arises.

- Less Planning Required: Requires less detailed planning and scheduling compared to preventive maintenance.

- Flexibility: Can be applied as and when needed, providing a flexible approach to unexpected issues.

Disadvantages of Corrective Maintenance:

- Unplanned Downtime: Can lead to unexpected equipment failures and production halts, disrupting operations.

- Higher Long-Term Costs: Repeated repairs can become more expensive over time compared to a preventive approach.

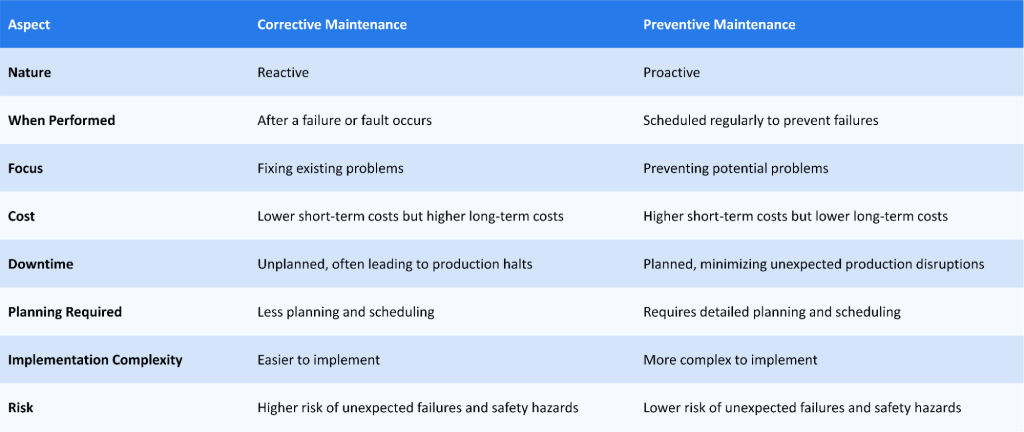

Corrective vs Preventive Maintenance – What is the Difference?

- Corrective Maintenance is reactive, addressing problems after they occur. It focuses on fixing equipment when it breaks down.

- Preventive Maintenance is proactive, involving regular inspections, servicing, and maintenance to prevent equipment failures before they happen. This approach aims to reduce the likelihood of unexpected breakdowns.

How to Reduce Corrective Maintenance?

Reducing the reliance on corrective maintenance involves adopting a more proactive approach to maintenance. Here are some strategies:

- Implement Preventive Maintenance: Regularly scheduled inspections and maintenance can help detect potential issues before they lead to equipment failure.

- Adopt Predictive Maintenance: Utilize advanced technologies like IoT sensors and machine learning to predict equipment failures based on real-time data.

- Train Maintenance Staff: Ensure that maintenance personnel are well-trained to perform preventive and predictive maintenance tasks effectively.

- Invest in Quality Equipment: High-quality equipment is less likely to fail and require corrective maintenance.

Final Thoughts on Corrective Maintenance

Unexpected equipment breakdowns can disrupt operations—but that’s where corrective maintenance comes in. It plays an essential role in getting things back on track quickly when things go wrong. But to truly stay ahead, it’s important to not just fix issues reactively. Combining corrective maintenance with preventive and predictive strategies creates a more reliable, cost-effective, and efficient maintenance approach.

At TeroTAM, we understand that every facility faces unique challenges. That’s why our connected CMMS platform is designed to help you respond faster, plan smarter, and reduce unexpected downtime. Whether you’re just starting to organize your maintenance or aiming to upgrade to a more proactive model, we’re here to support you every step of the way.

Have questions or ready to get started? Talk to our team today—we’re just a message away.